Radiated Emissions by the heatsinks of microprocessors.

- Francesco Poderico

- Jan 1, 2023

- 3 min read

My current client has four heatsinks in his design, so in my solution, I'm designing some precautions to minimize emissions in the final design. In my experience, this error is very common, so I would like to discuss it one more time. I hope you won't make the same mistake again in your design.

The solution is quite simple to implement, but depending on the heatsink you have selected, it may cause an extra step in the manufacturing process.

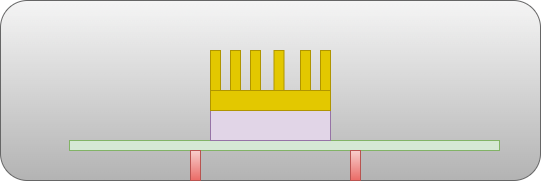

Here is an example of a microprocessor or FPGA that requires a heatsink.

FIGURE 1. A PCB is insulated from a metallic enclosure. A Microprocessor and a heatsink.

Imagine that our equipment is enclosed in a metal enclosure to make our point even stronger.

Here's the question. Is it possible for this system to produce radiated emissions? Is it possible to produce conductive emissions as well?

In order to answer this question, we need to create a model of the system and analyze it.

The first thing to notice is that normally, microprocessors and heatsinks are only insulated in DC, but at high frequencies, a parassitic capacitor couples the switching voltage from the microprocessor to the heatsink... Let's call this capacitor Cp1.

In our system, GND plane represents the reference plane, and current flows from the microprocessor to the heatsink through the parasitic capacitor Cp1. In a previous post, we discussed how a heatsink works exactly like a patch antenna. However, this time the heatsink is inside another enclosure! For the sake of this discussion, let's assume the heatsink isn't functioning as a patch antenna.

As the heatsink faces the metal enclosure, we can assume that there is another parasitic capacitor between the heatsink and the enclosure in this system. Let's call this capacitor Cp2.

Thus, the current is now energizing the heatsink, and now it is the metal enclosure that appears to behave like a patch antenna. This is particularly true if the GND plane is enclosed in a metal enclosure.

What can we do to reduce the emissions from this structure?

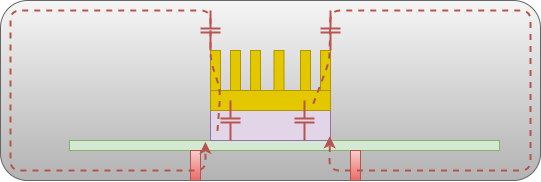

Take a look at the following drawing:

FIG 2. We can see in the above drawing the current path. now the enclosure can behave like a patch antenna.

Cp1 and Cp2 cannot be removed, but the current path across the enclosure can be broken in several ways.

The first method is to connect the enclosure to the GND plane.

There are several ways to achieve this, including connecting the GND plane to the chassis in DC if possible. If this is not possible, for safety reasons, we can use a Y capacitor instead. From my experience, the value of the Y capacitor is not relevant; in my tests, I have used different values, and they almost always work.

In addition, at frequencies above 1 MHz, a Y capacitor behaves like an inductor... Y capacitors usually have resonance frequencies around a few hundred kHz. However, the Y capacitor value is still a significant order of magnitude that Cp1, which makes this trick work.

When we do this... we are "breaking" the structure of a patch antenna.

We can also connect the heatsink body to PCB GND (microcontroller reference plane, or 0V) instead. I sometimes connect this at 2 different points (most heatsinks have 2 screws, and these screws can be wired to the PCB 0V).

After we have done this, the current loop will look like this:

FIG.3 . We have now drastically changed the HF current path and, therefore the RF emissions.

In this case, emissions have been drastically reduced.

When designing, make sure that you choose a heatsink that allows you to connect the heatsink body to the PCB 0V, and you should be fine.

What if the enclosure is not made of metal? Would we still have a problem?

Based on my experience, I would estimate that 30% of designs have problems. As a result, the heatsink acts as a path antenna in this case.

The cure is still the same, either connect the heatsink to the 0V (if you can in 2 points).

Now, most heatsinks for FPGAs and microprocessors have 2 screws on the side plate. Why don't we use these screws to eliminate this hassle?

So try to galvanically connect those screws to your PCB and you should be fine.

This is my first post of 2023 after a very busy 2022 December. I hope you have enjoyed it.

Comments